Medical Research Vision System

ChallengeThe customer needed a system to evaluate a new technique of using an adhesive to assist in attaching tendon to bone. Operating under repeated stress of motion, the customer wished to capture the strength of the connection, looking for the failure point of the adhesive.

The customer was also interested in what happened with the adhesive joint leading up to the breakaway point. SolutionWe created a system consisting of a FireWire camera and a data acquisition card to monitor the movement of the stress inducer. The software was written with LabVIEW and NI IMAQ Vision.

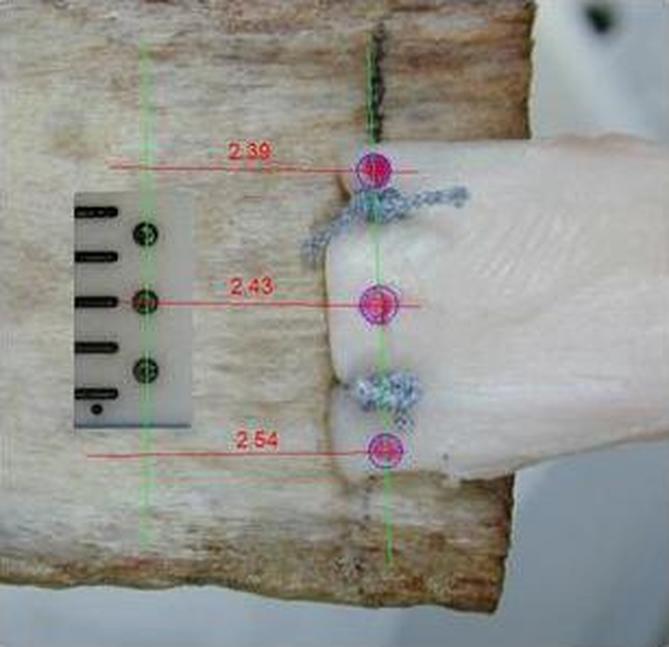

A special fiducial marker was used as the reference point for the bone and as a calibration reference, making precise measurements possible. Once the bone is attached, a marker is used to mark the tendon at key locations, which the software then coordinates with the fiducial. |

Accurate measurements are made in real time to watch the movement of the tendon during each motion sweep. A snapshot image is saved at the apex of the movement. After the test is complete, the apex images are assembled together into a movie that shows how the adhesive responded to the peak stress.

The system features include:

The system features include:

- Fiducial marker provides calibrated reference for precise distance measurements

- DAQ hardware interfaces to stand-alone voice-coil motion control

- Captures images at the apex of each mechanical cycle and creates a movie of the peak stresses and breakaway event

- On-screen overlay of reference lines and measurements, measurements are updated live for instant feedback

- Graphing of displacement over time to chart the adhesive performance

- Logged data file for post-processing

Technical Details

This system was created using National Instruments IMAQ Vision with an ISG Lightwise FireWire camera. The software was developed in LabVIEW.