Automated Test Equipment (ATE)

|

Advantages of ATE

ATE is used to automate and streamline the testing process with several advantages over manual testing.

|

Fast

Automated tests are nearly always faster than a manual test, often much faster. We build many systems where a manual test process that takes 5-10 minutes to perform can be done in under a minute. Accurate

Test results are read directly from measurement instruments, always using the same wiring and signal paths to maximize the accuracy of each measurement. Consistent

Unlike a manual test operator, an ATE runs the same program every time, following the precise process and timing, and faithfully recording all the results. Traceable

Test results are presented in reports, which can be archived with each device under test. Results can also be saved to a database for additional data security and traceability. |

Types of ATE Systems

We build custom test equipment, specifically-designed for your device. There are several types of ATE that we design and build.

|

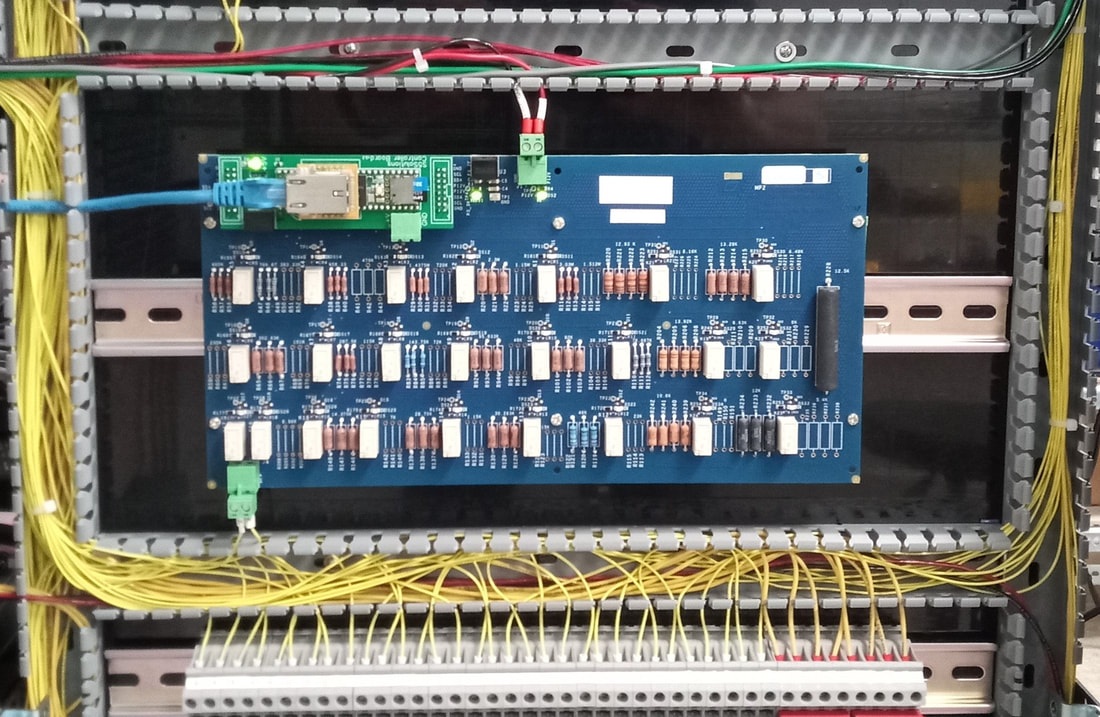

Functional Test

Functional testers test the operation of each of the parts of the PCB or assembly. A functional tester typically powers up the board and connects to all the inputs and outputs so the board behaves as if it is installed. The tester then provides combinations of stimuli and verifies the proper response to every situation the board must handle. This is a complete functional test of the board. Functional testers can be found In-House for companies doing there own production as well as at contract manufacturers. We provide testers for both scenarios. End-Of-Line Manufacturing Test

These are often Functional Testers that are specifically at the end of the production line. They perform tests on each device as it comes off the line. Often the next step is installation into a larger assembly, so this is the last opportunity to have access to all the test points for testing. Design Validation Test

A Design Validation Test (DVT) is a tool usually used by the designers of the board to validate the performance of the board to the specification. These tests are usually much more thorough than those in production testing. It tests the capability of the design to handle unexpected conditions, such as over and under voltage, signals out of range, current overloads, and other stresses. Test outputs are often large sets of data, such as scope captures of events of interest, as opposed to simple Pass/Fail results. Product Characterization

Similar to a Design Validation Tester, a Product Characterization Tester is used by the designers to gather information about the design itself, as opposed to a specific unit being tested. This type of test is usually going to be a specific test program running on a Design Validation Tester and will usually run on a sample set of UUTs to help validate the design from a statistical standpoint. In-House Testing

Clients that do their own manufacturing in-house will want to have a functional tester to validate each of the devices they make. This could be used in a hybrid model as well, where a contract manufacturer may build a board assembly but not test it. The client would set up their assembly line starting with automated testing of each assembly before building into the complete system. Contract Manufacturing Testing

Contract manufactures (CMs) often require their customers to provide a test system to verify the boards that they build. Some CMs will provide building a tester as a service for the client. We work with our clients to design and build testers for them to provide to CMs. Incoming Inspection

For clients that are using a contract manufacturer, it is common for them to have their own copy of the tester. They use this for incoming inspection to spot check boards as they get them from the CM. They may also use it for rework and repairs of boards. |

Learn more: What is ATE?, ATE Basics